Product Catalog

Contact Us

Contact :

Sales Team

Email :

hello@raunik.com

Phone&Whatsapp :

+91 9873070702

Address :

E-45, Sector 63, Noida, U.P. 201301

Subscribe

If you are interested in our products and RAUNIK, welcome to leave a message, we will reply immediately.

Lithium Ion Battery Manufacturing Machines | Lithium Ion Battery Assembly & Testing Machines

Here we will show you all the machines required for Manufacturing (Assembly & Testing) of Lithium Ion Battery Packs .

Cell Grading Machine / Cell Capacity Machine / Life Cycle Tester Machine

The first step in battery pack manufacturing is to test the capacity of incoming cells and grade them according to their capacities.We have to charge to full capacity and discharge the cell to check its capacity and then we have to charge the cells to same voltage which is normally its nominal voltage as prescribed by the manufacturer. It is recommended to do grading of 100% incoming cells but some clients prefer to do 30-50% grading if the cells are coming graded from cell factory .

| Cylindrical Cell Grading Machine | Prismatic Cell Tester or Pouch Cell Tester | Life cycle Tester for Cylindrical /Pouch, Prismatic Cells |

|---|---|---|

| 5V 3A , 5V 6A 512 channels Available in Linear/Regenerative (to save electricity) | 5V 10A to 5V 500A Customized number of Channels Regenerative | 5V 10A 16 channels, 5V 20A 8 channels Linear/Regenerative |

|  |  |

Voltage & IR Lithium Cell Sorting Machines

After Capacity Grading/Testing process, we have to sort the cells according to their Voltage & Internal Resistance (IR). THis process is done so that similar cells (as per V & IR) are grouped together to form battery pack to get the best performance otherwise the battery pack will have lot of performance and balancing issues.

| 5 Channel Universal Cylindrical Cell Sorter | 10 Channel Universal Cylindrical Cell Sorter | Automatic Prismatic Cell Sorter | HK 3561 | Hioki 3561 |

|---|---|---|---|---|

| Can sort cylindrical cells (18650, 21700, 26700,32700) into 5 channels (4 good and 1 Not Good) | Can sort cylindrical cells (18650, 21700, 26700,32700) into 10 channels (9 good and 1 not good) | Can sort Prismatic Cells | Highly Accurate Manual/Automatic both types can be used Max Voltage 60V | Highly Cost Effective Manual/Automatic both types can be used Max Voltage 60V |

| Can be used with Hioki 3561 or HK 3561 | Can be used with Hioki 3561 or HK 3561 | Can be used with Hioki 3561 or HK 3561 | ACIR 1μΩ ~ 3kΩ, +/- 0.5% | ACIR 1μΩ ~ 3kΩ, +/- 0.5% |

|  |  | Automatic Lithium Cell Sorting Machine / Cell Sorter Machine |  |

Spot Welding Machines for Lithium Battery (Spot Welders)

| Manual Spot Welding Machine | Double Side Automatic Spot Welding Machine | Laser Welding Machine |

|---|---|---|

| For spot welding of nickel strip to cylindrical lithium cells Transistor (Resistance) or Transformer based Electrical or Pneumatic heads 5000A / 8000A / 10000A | Can spot weld both positive and negative terminal of cylindrical lithium cells at same time Electric Servo Motor controlled Welding Heads Transistor power supply With Chiller for cooling Maximum Jig Size 350mm x 600 mm Highly Productive Program controlled to spot weld multiple battery packs at same times 5000A / 8000A / 10000A | For Welding Bus bars to Prismatic Cells 2000W / 4000W / 6000W |

BMS Tester (Battery Management System Testing Machine)

BMS is also called as the heart of the lithium battery because it is the responsibility of the BMS to control each cell of the battery, communicate with external devices, manage State of Charge calculations, keep measuring temperature and Voltage and safeguards both user and battery itself by ensuring that the battery is working within its safe working parameters.

Available in 24S 120A , 24S 200A 32S 120A & 32S 200A models

Battery Ageing Machine / Battery Charge Discharge Machine

After the battery is fully made, we must calculate its Capacity before despatch . The battery ageing machine is used to caculate the capacity of the battery using charge and discharge functions. The battery is charged to full and then discharged completely to determine its capacity . After determining the capacity, the battery is charged to its nominal voltage to be despatched to the customer.

Characteristics of the battery ageing machine are : -

- Regenerative - Energy feedback function / Linear

- CC CV mode Charging / CCD Discharge Mode

- TCP / IP Protocol Communication

- Data Saving in Excel

- Temperature Monitoring during Charge/Discharge

Models Available

- 9-99V 10A Charge 20A Discharge BCDS

- 100V 30A 4 channels BCDS

- 100V 60A 2 channels BCDS

- 75V 40A 4 channels BCDS

End of Line Battery Comprehensive Tester

After the battery pack is completed , Battery Comprehensive Tester is used to find the quality of battery based on different tests like Charging Test, Discharging Test, Over Charging Current Test, Over Discharging Current Test, Open Circuit Voltage of Battery Terminal 1 and 2, Short Circuit Test, AC IR test, DC IR test. We set the parameters in the software and the tester shows if the battery is Pass/Fail on the tested paramters. The tests usually takes only a few seconds (7-8 seconds)

Models Available

100V 120A, 200A, 120V 120A , 120V 200A Battery Comprehensive Tester

Other Misc Machines

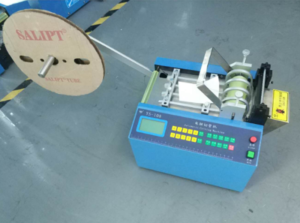

Nickel Strip Cutting Machine for cutting nickel strips to weld on Lithium Battery

PVC Shrink Wrap Machine for Lithium Battery Packing

Laser Cleaning Machine

CCD Polarity Tester

FAQS:

Manufacturing of Lithium battery packs can be started with a low investment of around 15 lakh rupees for a small set up and can be customized according to the target industry like car battery manufacturing plant or 2W or 3W battery manufacturing plant and can cost around 20 lakh rupees upto 1 crore rupees depending upon the number of battery packs to be produced per day, the Wattage of battery, the type of cells, target application (car, two wheeler,three wheeler, solar , ess, etc) and the amount of automation that is required.

Manufacturing of lithium ion battery packs can be started immediately by consulting an expert in lithium battery technology and Machinery like Raunik GreenTech . We can explain to you the different types of lithium batteries that can be manufactured, the markets that you can explore like 2W lithium battery market, 3W lithium battery market, solar street lights, solar power battery back up, Industrial Energy Storage Systems , Electric Cycle Battery, Battery Swapping Station etc and many more.

After understanding the requirements of battery packs to be produced per day and the type of battery pack, we can give you an estimate of Machines required to run your battery plant .We will also show you live demo of all machines in our factory in Noida, Uttar Pradesh.We will also guide you on raw materials and share industry experts for different types of raw material like Cells, BMS, Nickel Strips, Connectors etc so you can buy the raw material directly from manufacturer and save on costs.

You can start your lithium battery manufacturing plant immediately after buying the machines from Raunik GreenTech !!

The Lithium battery is connected by assembling and connecting the different lithium cells in Series ( to increase Voltage) and in parallel (to increase Capacity) with a Battery Management System to control the battery .

A lithium battery consists of a lot of small parts mainly lithium cells, BMS, wires, epoxy sheets, screws, metal/aluminium casing, etc

Product Catalog

Lithium Ion Battery Manufacturing Machines | Lithium Ion Battery Assembly & Testing Machines

Here we will show you all the machines required for Manufacturing (Assembly & Testing) of Lithium Ion Battery Packs .

Cell Grading Machine / Cell Capacity Machine / Life Cycle Tester Machine

The first step in battery pack manufacturing is to test the capacity of incoming cells and grade them according to their capacities.We have to charge to full capacity and discharge the cell to check its capacity and then we have to charge the cells to same voltage which is normally its nominal voltage as prescribed by the manufacturer. It is recommended to do grading of 100% incoming cells but some clients prefer to do 30-50% grading if the cells are coming graded from cell factory .

| Cylindrical Cell Grading Machine | Prismatic Cell Tester or Pouch Cell Tester | Life cycle Tester for Cylindrical /Pouch, Prismatic Cells |

|---|---|---|

| 5V 3A , 5V 6A 512 channels Available in Linear/Regenerative (to save electricity) | 5V 10A to 5V 500A Customized number of Channels Regenerative | 5V 10A 16 channels, 5V 20A 8 channels Linear/Regenerative |

|  |  |

Voltage & IR Lithium Cell Sorting Machines

After Capacity Grading/Testing process, we have to sort the cells according to their Voltage & Internal Resistance (IR). THis process is done so that similar cells (as per V & IR) are grouped together to form battery pack to get the best performance otherwise the battery pack will have lot of performance and balancing issues.

| 5 Channel Universal Cylindrical Cell Sorter | 10 Channel Universal Cylindrical Cell Sorter | Automatic Prismatic Cell Sorter | HK 3561 | Hioki 3561 |

|---|---|---|---|---|

| Can sort cylindrical cells (18650, 21700, 26700,32700) into 5 channels (4 good and 1 Not Good) | Can sort cylindrical cells (18650, 21700, 26700,32700) into 10 channels (9 good and 1 not good) | Can sort Prismatic Cells | Highly Accurate Manual/Automatic both types can be used Max Voltage 60V | Highly Cost Effective Manual/Automatic both types can be used Max Voltage 60V |

| Can be used with Hioki 3561 or HK 3561 | Can be used with Hioki 3561 or HK 3561 | Can be used with Hioki 3561 or HK 3561 | ACIR 1μΩ ~ 3kΩ, +/- 0.5% | ACIR 1μΩ ~ 3kΩ, +/- 0.5% |

|  |  | Automatic Lithium Cell Sorting Machine / Cell Sorter Machine |  |

Spot Welding Machines for Lithium Battery (Spot Welders)

| Manual Spot Welding Machine | Double Side Automatic Spot Welding Machine | Laser Welding Machine |

|---|---|---|

| For spot welding of nickel strip to cylindrical lithium cells Transistor (Resistance) or Transformer based Electrical or Pneumatic heads 5000A / 8000A / 10000A | Can spot weld both positive and negative terminal of cylindrical lithium cells at same time Electric Servo Motor controlled Welding Heads Transistor power supply With Chiller for cooling Maximum Jig Size 350mm x 600 mm Highly Productive Program controlled to spot weld multiple battery packs at same times 5000A / 8000A / 10000A | For Welding Bus bars to Prismatic Cells 2000W / 4000W / 6000W |

BMS Tester (Battery Management System Testing Machine)

BMS is also called as the heart of the lithium battery because it is the responsibility of the BMS to control each cell of the battery, communicate with external devices, manage State of Charge calculations, keep measuring temperature and Voltage and safeguards both user and battery itself by ensuring that the battery is working within its safe working parameters.

Available in 24S 120A , 24S 200A 32S 120A & 32S 200A models

Battery Ageing Machine / Battery Charge Discharge Machine

After the battery is fully made, we must calculate its Capacity before despatch . The battery ageing machine is used to caculate the capacity of the battery using charge and discharge functions. The battery is charged to full and then discharged completely to determine its capacity . After determining the capacity, the battery is charged to its nominal voltage to be despatched to the customer.

Characteristics of the battery ageing machine are : -

- Regenerative - Energy feedback function / Linear

- CC CV mode Charging / CCD Discharge Mode

- TCP / IP Protocol Communication

- Data Saving in Excel

- Temperature Monitoring during Charge/Discharge

Models Available

- 9-99V 10A Charge 20A Discharge BCDS

- 100V 30A 4 channels BCDS

- 100V 60A 2 channels BCDS

- 75V 40A 4 channels BCDS

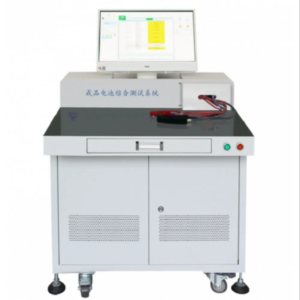

End of Line Battery Comprehensive Tester

After the battery pack is completed , Battery Comprehensive Tester is used to find the quality of battery based on different tests like Charging Test, Discharging Test, Over Charging Current Test, Over Discharging Current Test, Open Circuit Voltage of Battery Terminal 1 and 2, Short Circuit Test, AC IR test, DC IR test. We set the parameters in the software and the tester shows if the battery is Pass/Fail on the tested paramters. The tests usually takes only a few seconds (7-8 seconds)

Models Available

100V 120A, 200A, 120V 120A , 120V 200A Battery Comprehensive Tester

Other Misc Machines

Nickel Strip Cutting Machine for cutting nickel strips to weld on Lithium Battery

PVC Shrink Wrap Machine for Lithium Battery Packing

Laser Cleaning Machine

CCD Polarity Tester

FAQS:

Manufacturing of Lithium battery packs can be started with a low investment of around 15 lakh rupees for a small set up and can be customized according to the target industry like car battery manufacturing plant or 2W or 3W battery manufacturing plant and can cost around 20 lakh rupees upto 1 crore rupees depending upon the number of battery packs to be produced per day, the Wattage of battery, the type of cells, target application (car, two wheeler,three wheeler, solar , ess, etc) and the amount of automation that is required.

Manufacturing of lithium ion battery packs can be started immediately by consulting an expert in lithium battery technology and Machinery like Raunik GreenTech . We can explain to you the different types of lithium batteries that can be manufactured, the markets that you can explore like 2W lithium battery market, 3W lithium battery market, solar street lights, solar power battery back up, Industrial Energy Storage Systems , Electric Cycle Battery, Battery Swapping Station etc and many more.

After understanding the requirements of battery packs to be produced per day and the type of battery pack, we can give you an estimate of Machines required to run your battery plant .We will also show you live demo of all machines in our factory in Noida, Uttar Pradesh.We will also guide you on raw materials and share industry experts for different types of raw material like Cells, BMS, Nickel Strips, Connectors etc so you can buy the raw material directly from manufacturer and save on costs.

You can start your lithium battery manufacturing plant immediately after buying the machines from Raunik GreenTech !!

The Lithium battery is connected by assembling and connecting the different lithium cells in Series ( to increase Voltage) and in parallel (to increase Capacity) with a Battery Management System to control the battery .

A lithium battery consists of a lot of small parts mainly lithium cells, BMS, wires, epoxy sheets, screws, metal/aluminium casing, etc

Contact Us

Contact :

Sales Team

Email :

hello@raunik.com

Phone&Whatsapp :

+91 9873070702

Address :

E-45, Sector 63, Noida, U.P. 201301

Subscribe

If you are interested in our products and RAUNIK, welcome to leave a message, we will reply immediately.

Products

- About Us

- Our Factory

- Certificates

ABOUT US

Raunik GreenTech Pvt Ltd was established in 2022, with the aim of providing transparency and demo factory tour to the prospective entrepreneurs who want to set up their manufacturing facility for lithium battery packs, thereby making a way for more green energy solutions providing, companies.

Years Experience

Years Experience

Years Experience

Years Experience

READY TO LEARN MORE ABOUT RAUNIK GREENTECH ?

Strong R&D ability,hundreds of skilled workers, professional workshop, advanced production equipment and strict inspection, RAUNIK is ready, welcome to contact us.

WHAT CUSTOMERS SAID